one- and two-sided PCBs

From simple to complex

Single-sided PCBs, also known as single-layer PCBs, are the simplest and most commonly used type of PCB. They consist of a copper layer applied to an insulating substrate such as FR4 (glass fiber reinforced epoxy resin).

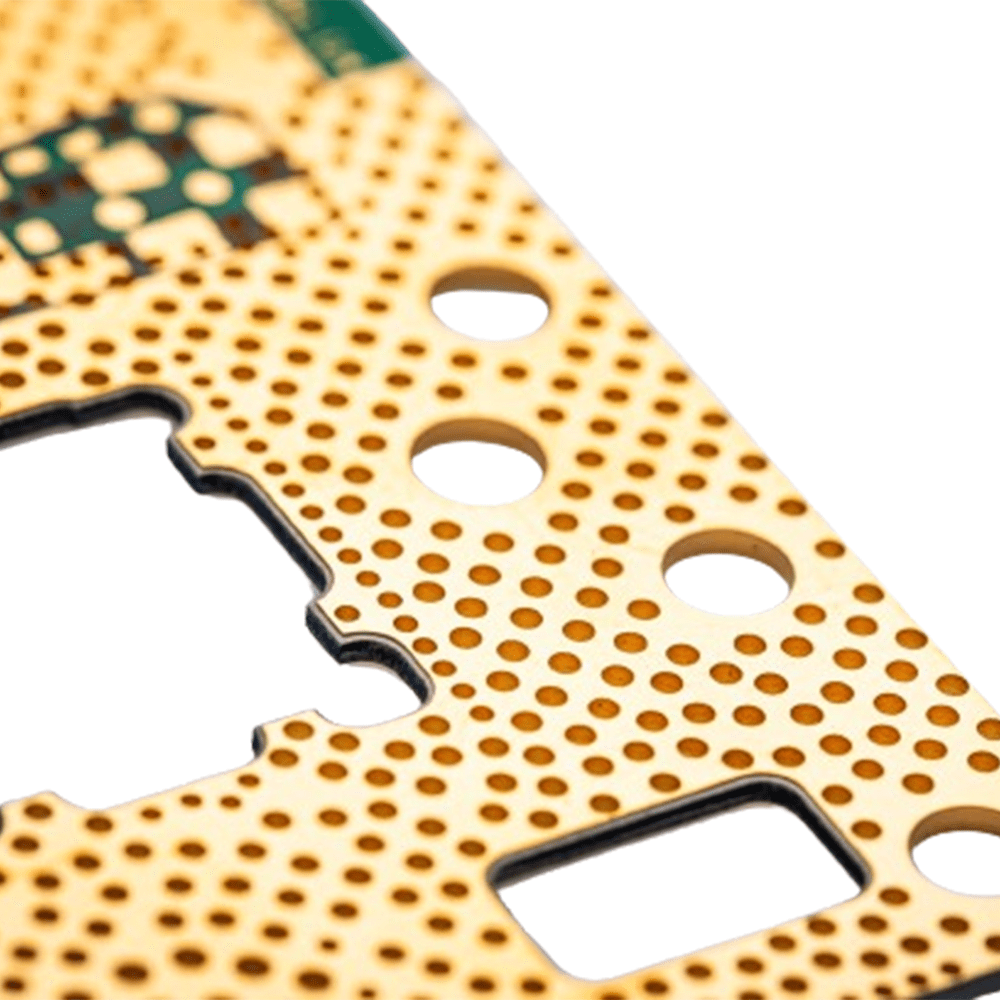

Double-sided PCBs consist – as the name suggests – of two copper layers applied to both sides of the substrate. The two copper layers can be electrically connected to each other via vias.

Double-sided PCBs therefore offer more flexibility and enable more complex circuits.

The choice between single-sided and double-sided PCBs depends on the requirements of the project in question. Single-sided PCBs are generally cheaper and easier to manufacture, while double-sided PCBs are suitable for more complex circuits and denser component arrangements that cannot be accommodated on a single side.

Applications

The areas of application for 1-sided and 2-sided PCBs are diverse.

On the left you will find some examples of applications for 1-sided PCBs, on the right for 2-sided PCBs:

Simple electronic devices

Household appliances

Consumer electronic products

Industrial electronics

Automotive industry

Materials

ISOLA IS400 – TG150°Panasonic R1566W – TG150°NanYA NP-175F-BH – TG150°

As a prototype manufacturer, we are always ready to integrate new materials into our production and subject them to extensive testing.