Rigid-flex PCBs

The best of 2 worlds:our rigid-flex printed circuit boards

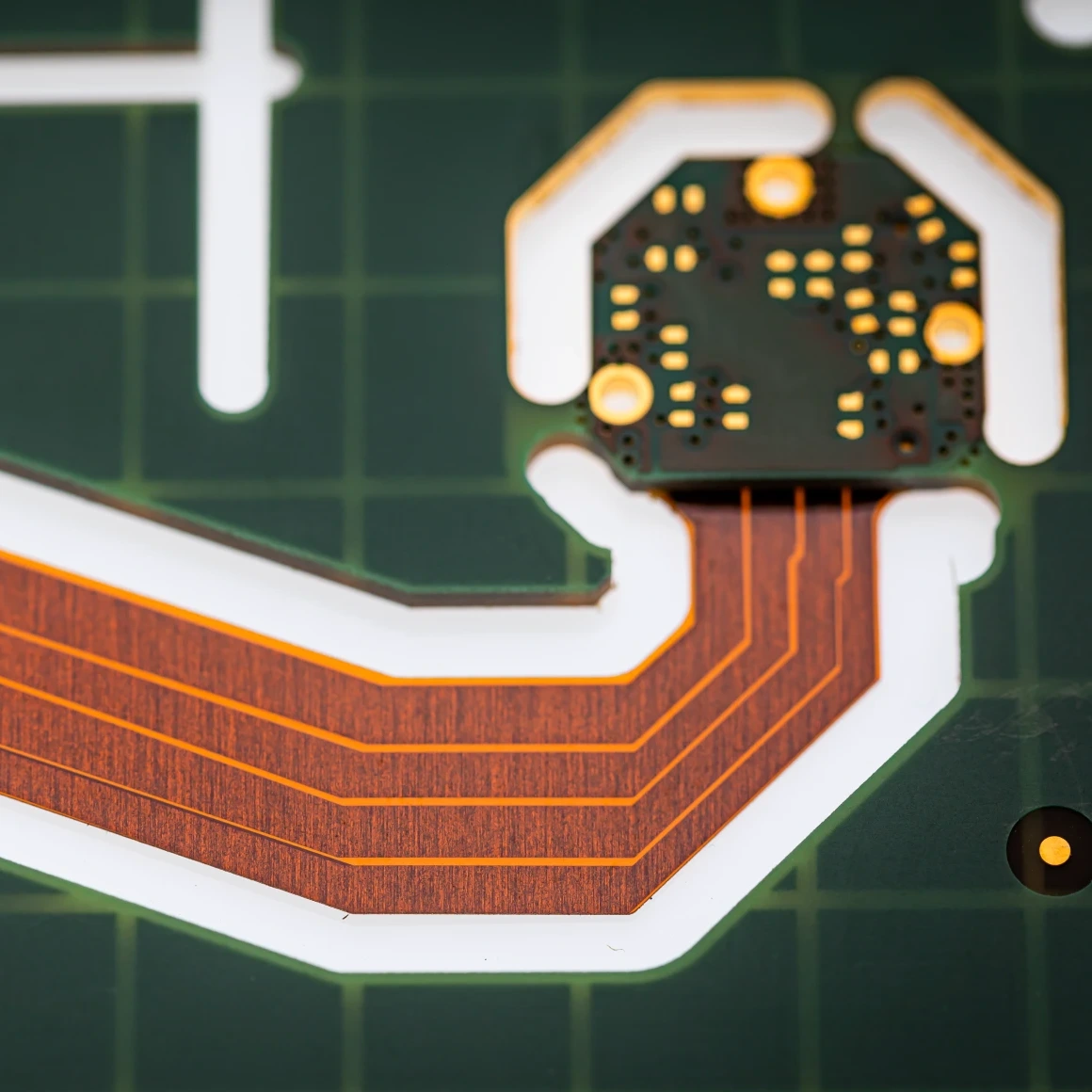

As the name suggests, rigid-flex printed circuit boards consist of both flexible and rigid layers that are pressed together. One or more flexible polyamide films form the basis. The required rigid parts are pressed into these at the defined points. The continuous flexible film means that cables, connectors and line components are no longer required.

The main advantage is that there are virtually no limits to the PCB design: The flexibility in design means that many components can be accommodated in the smallest possible space, which in turn reduces weight and volume. Rigid-flex PCBs are therefore ideal for all applications where miniaturization is important. Rigid-flex PCBs are also the material of choice for applications with high dynamic loads.

In principle, inner and outer layers can be flexible. This means that there is a very wide range of construction options.

There is also a large selection of different materials available for rigid-flex printed circuit boards.

We will be happy to work with you to find the perfect solution for your application.

By the way: All rigid-flex PCBs are also available from us as PCB prototypes as part of our express service.

Applications

Automotive industry

Portable electronics

Industrial automation

Defense industry

Consumer electronics

Materials

Dupont Pyralux APDupont Pyralux LFPanasonic Felios Flex-SeriePanasonic R1566WPanasonic R1566SISOLA IS400Shengyi Autolad 1Shengyi Autolad 2GHNanYA NP-175F-BHElite EM-370(5)Elite EM-370(Z)

As a prototype manufacturer, we are always ready to integrate new materials into our production and subject them to extensive testing.